Look with all your eyes, look.

– Jules Verne

Turning a wrench an eighth of a turn at a time, thinking this will take forever. There has to be a better way.

So. What would work? A wrench small enough to make a complete turn in a tight space.

Idea, concept, imagination. Action. (Previous story, more background, linked here.)

After a stay in the hospital, the original USAF tech school assignment of remove and replace (easy) the hydraulic reservoir was gone. Instead, the toughest possible project possible handed out: Remove and replace a most challenging hydraulic component on a T-38 Talon trainer, a flight control valve. Deep breath. Read. Proceed. One step at a time.

Because the T-38 (engines removed, used for training), is sleek, agile performance aircraft, all is precision engineered to fit together and work. Which also means space is at a premium. A challenge for a mechanic, an exquisite intricate puzzle.

A hex nut line called for a wrench to loosen – but because of other lines and parts woven in and out and around in such a compact space – the hex nut line for hydraulics could be turned only an eighth of a full rotation. Which meant inch, inch, inch. There must be a better way. What was the solution?

Ask a question of the formidable (female) hydraulics civil service instructor. She was a pioneer, a woman in a military aviation hydraulics technical school. She was very good, accomplished, with experience and knowledge. She didn’t talk much, was available at a desk located in front of a two-door locked cabinet. So I asked, “Is there a wrench available that would make a full rotation?” A slight smile appeared on her face; she turned and went to the board, unlocked it. Removed a stubbed wrench, placed a metal chit in its place on the board. Placed in my hands a cut-in-half special tool – an offset open-end wrench. It was custom-made (a hack so to speak) for a specific purpose. The hardened steel had been sanded smooth, and guess what? That wrench worked like a charm for making full rotations in that cramped compartment under the aircraft. In just a few minutes, the valve was removed. Documentation done. One half of the test was complete. The instructor verified the work for a final grade. Now it was time to replace the part (on the flightline it would be a new valve). Do the paperwork, have the work inspected, sign off.

What is the point and how does knitting relate to aviation applied physics, manufacturing, reading widely? Thinking logically, applied creativity.

The accrued knowledge even at a young age (18) as a flightline mechanic in the U.S. Air Force, leads to visual thinking.

Knitting incongruous arenas of life together, using inventiveness and engineering to think of what is possible. Then creating steps or finding them to get to a goal led to many chapters in life and business over the years. Much travel added to seeing things differently. Then, a business startup, then another venture. Solo entrepreneur. Lessons learned from a life of learning – walk through worlds and build doors or find them to enter/exit silos. Figure it out. One person can be both a knitter and an engineer; a mechanic and a parent. A writer and a horse trainer. A person who thought math was difficult, but found knitting to be a language that is a map which can be applied to computing, coding – building in three dimensions plus geometry. To make something from nothing using an idea a concept, process. Aviation, life, puzzling out what is next. Languages unlock the journey; apply the knowledge.

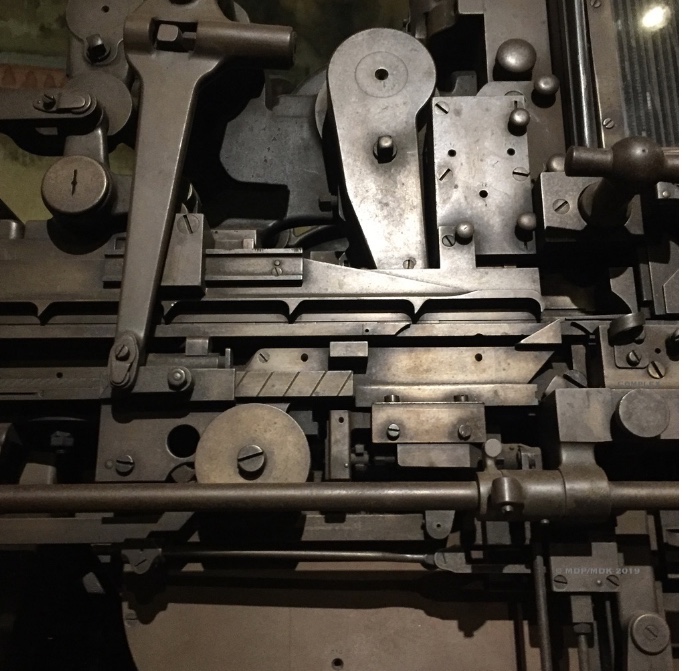

Note: The machine depicted is Mark Twain’s The Paige Compositor, which may be viewed at the Mark Twain House & Museum, Hartford.